Toll Free: (800) 888-8987 | Phone: (440) 835-3540 | office@ramsensors.com

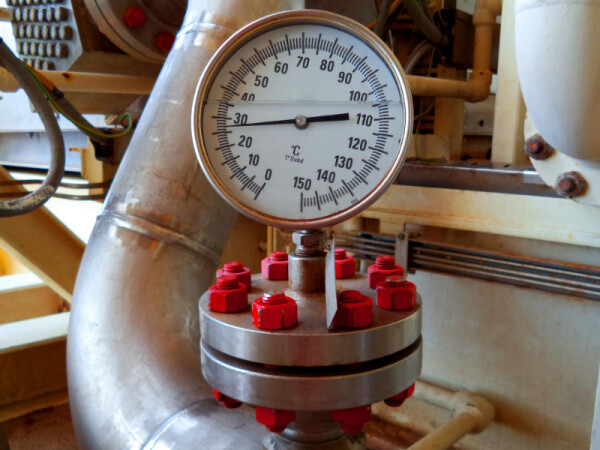

Proper Placement of Thermowells For Your Industrial Thermometers

The performance and life expectancy of a thermowell are directly tied to how and where it will be used. You want the best performance and longest lifespan from your temperature sensing devices, so understanding this relationship is essential.

How to Properly Configure Thermowells

Every job situation requires the right tool and the right specs. You've likely heard the old expression "a poor workman blames his tools." But it would be more accurate to say that a poor workman makes bad decisions about which tool to use and when to use it. Improper installation of thermowells leads to preventable failures and performance problems. And that prevention comes from using the expertise and experience of a company like RAM Sensors.

When configuring thermowells for industrial applications, the following practices must be followed:

Correct Placement

Inaccurate readings can result if multiple thermowells are placed too close or too far apart. To avoid conflicting interaction, RAM Sensors always observes correct inline or offset placement, resulting in the most reliable data and giving you the best results.

Exposure & Length

Too much exposure of a thermowell's stem will still yield accurate readings, but will also produce more wear and tear. Exposure of too little of the stem results in less accuracy. RAM Sensors has the industry knowledge and experience to establish the correct amount of stem exposure to the temperature sensing process.

Location of Pipes

A thermowell's location in relation to the process flow has an enormous impact on measurement accuracy. This is particularly true of pipeline elbows. A choice of upstream or downstream location must be made to fit the individual situation, and RAM Sensors is here to help you make those choices.

Flow Dynamics

The process flow can be steady or pulsating, liquid or slurry, and various combinations of these types. Optimum placement of the thermowell is influenced by flow dynamics. Also, a pipe's diameter and distance between other pipeline elements contribute to a thermowell's ideal location.

Contact RAM Sensors for Expertise on Thermowell Installation

At RAM Sensors, we are experts in the installation of thermowells and understand how they interact with other temperature sensing devices. We also account for device composition and the dynamics of the environment. A thermowell's field performance is directly affected by these factors, along with insertion depth and stem length. That's why our customers trust RAM Sensors' expert thermowell design and installation.

With over 40 years of experience serving industrial clients, we bring the industry's top knowledge to your operation and are your first choice when it comes to the design and location of thermowells and pipeline architecture. Working with your technical engineering team, we can assure you the best, most reliable temperature sensing results. Contact RAM Sensors today for more information about our thermowell design, manufacturing, and installation.